What works we perform.

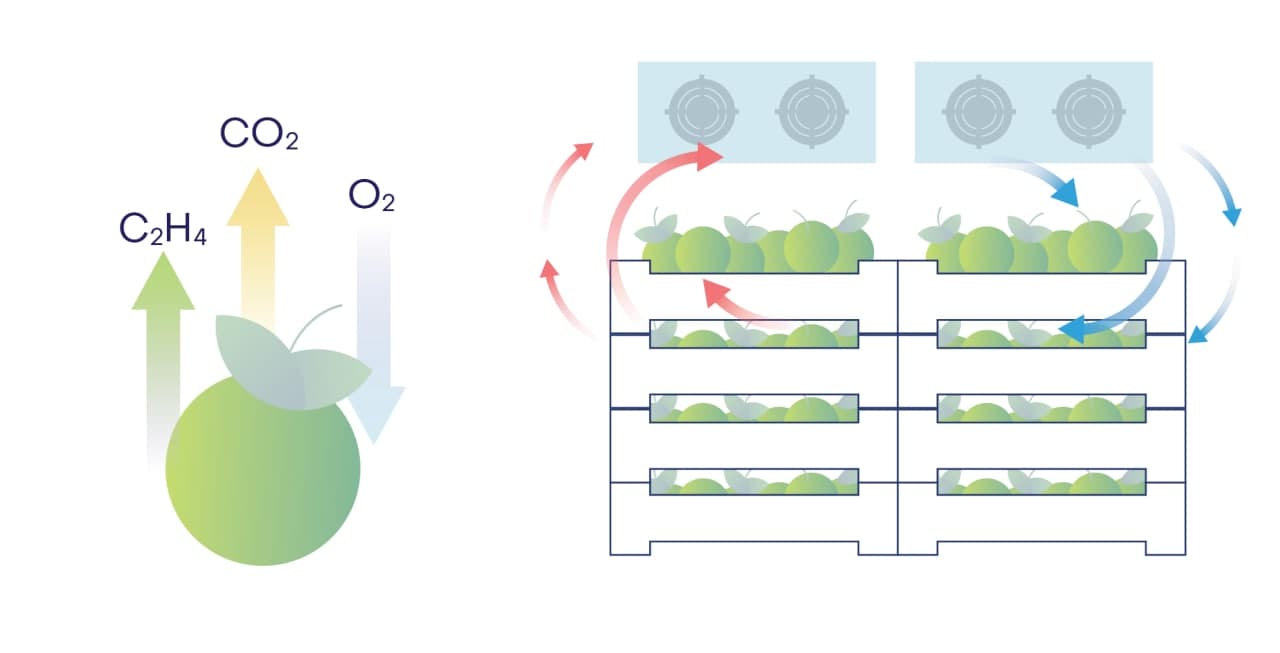

Quality storage of fruits in the fruit warehouse requires:

- maintenance of optimal concentration of gases (oxygen (O2) and carbon dioxide (CO2),

- as well as control of temperature and humidity.

These indicators are important for long-term storage, loss reduction, affect the appearance of fruit and weight maintenance.

There are three main systems for storing fruit:

Controlled atmosphere (CA)

To slow down the ripening of fruits, the composition of the atmosphere should maintain an oxygen level of O2 — 5-10%, and carbon dioxide, depending on the variety and species, 1-10%. Equipment used: adsorber and scrubber.

Ultra Low Oxygen (ULO)

This system is used to preserve the freshness of apples and pears in storage rooms by reducing the level of oxygen O2 (1-1.5%) and increasing the level of carbon dioxide CO2 (1- 5%). This composition of the atmosphere slows down the metabolism of fruits. With the help of a nitrogen generator, oxygen is displaced from the chambers.

Dynamic Controlled Environment (DCA)

The most modern system by which in a short period you can achieve and maintain a minimum concentration of oxygen O2 (0.2-0.8%) and carbon dioxide CO2 (0.5-5%), thereby increasing the shelf life without the use of chemicals. The minimum level of oxygen is selected individually for the kind and type of product.

The following equipment is used to equip fruit warehouses:

- Refrigeration equipment ensures air circulation in the storage

chamber and the optimum temperature. We use 2 types of

refrigeration systems: with direct evaporation and with

intermediate refrigerant. - Nitrogen generator supplies high-purity nitrogen to the

chamber and displaces oxygen from the chambers. - Scrubber absorbs carbon dioxide, which is formed in the

storage chambers, and prevents damage to the fruit. - Humidifiers maintain the required level of humidity, which

prevents the fruit from drying out. - Monitoring and dispatching system allows you to control and

automatically manage ventilation and refrigeration equipment

in a warehouse.

Comprehensive solutions for construction and equipment of

fruit warehouses.

We are competent in all the intricacies of fruit storage, so all stages of engineering are carried out in accordance with technological requirements. Full “turnkey” construction cycle.

Our experts will help you evaluate different types of refrigeration systems, select the most efficient and cost-effective technical solution that will meet your long-term maintenance requirements and budgets. We provide a warranty on the equipment from the manufacturer and the work performed.