To properly select the thermal insulation used in industrial refrigeration processes, system designers need to consider more than just operating temperatures.

Industrial process cooling systems can run at very low and even cryogenic temperatures. Under these extreme conditions, any design or installation flaws in the insulation system become evident promptly and may damage the system.

Most often this manifests itself in the formation of condensation on the outer shell or, in especially bad situations, ice on or in the insulation. System design deficiencies also increase the operating and capital costs of the refrigeration system. In the event of a violation of the flow of the technological process, the losses can be even greater.

Therefore, any industrial cooling system must be designed so that:

- limit the flow of heat;

- maintain a constant temperature;

- operate effectively;

To achieve these goals, almost all cooling processes require thermal insulation for:

- temperature control;

- limiting the flow of heat into the system;

- minimizing surface condensation.

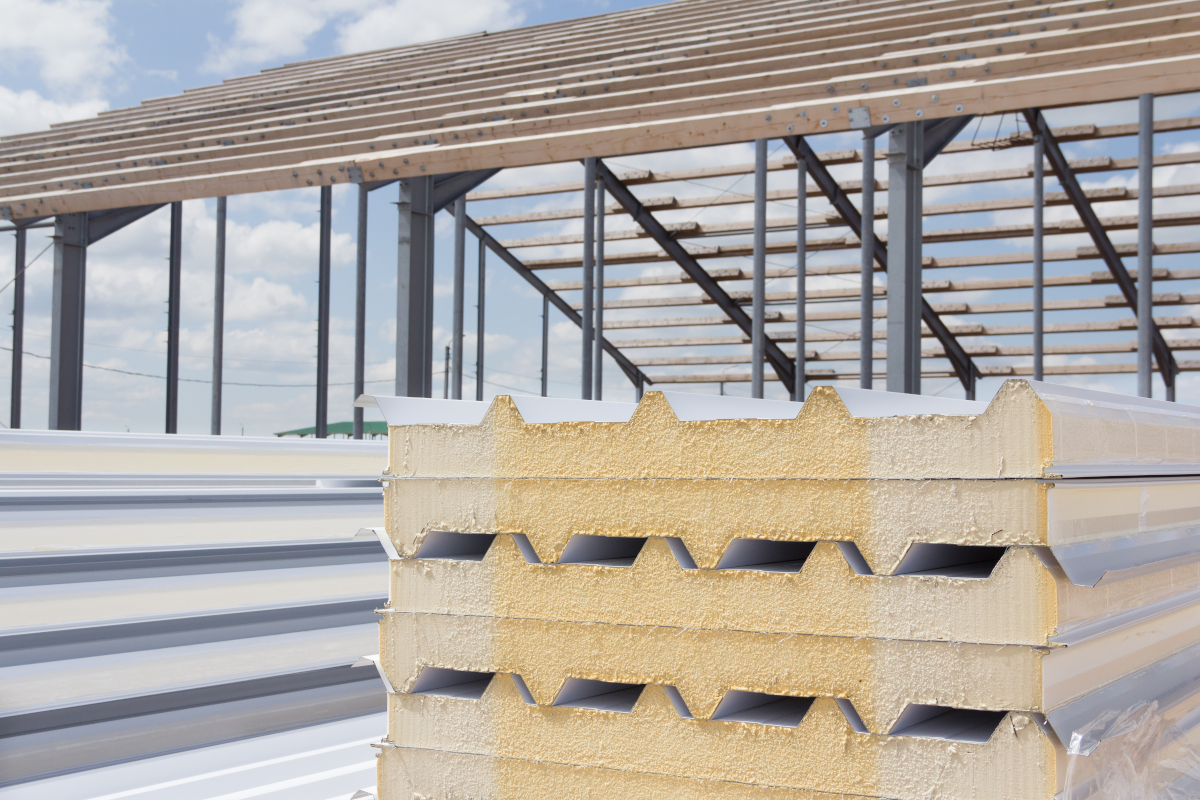

The most prevalent insulation materials used for the cooling of non-food and beverage industrial processes are polyisocyanurate (PIR) foam and cellular glass. Both of these materials have advantages that designers can use to get the most out of their systems.

PIR insulation is a rigid polyisocyanurate foam that can be used at both ultra-low cryogenic temperatures and temperatures up to 149°C. This type of insulation has an average level of compressive strength, which allows preventing damage to the system from misuse or impact.

When deciding on insulation material, system designers should consider the following characteristics:

- insulation thickness;

- compressive strength;

- vapor barrier;

- metal shell;

- environmental conditions.

To make the right choice, these characteristics must be compared with the unique requirements of each project.

Insulation thickness

The required thickness always depends on the thermal conductivity of the insulation — the lower the thermal conductivity, the better the insulation properties of the material. This means that materials with higher thermal conductivity must be thicker for achieving the same performance as materials with lower thermal conductivity.

The thickness of the insulation can affect the overall cost. First, the greater thickness requires the use of additional insulation as well as additional auxiliary materials such as joint sealant and metal shell. Secondly, the larger the outer diameter of the insulation system, the larger the pipe supports and racks should be.

It is important to take into account that the coefficient of thermal conductivity cannot be precisely represented by a single value (it is highly dependent on temperature). In most cases, the thermal conductivity value at an average temperature of 24°C is used as a rough estimate of performance when designers compare the materials.

Compressive strength

Insulation thickness is crucial for the effectiveness of industrial refrigeration insulation systems. However, compressive strength is crucial as well, because this characteristic can help avoid damage to the system and vapor barrier from external forces.

At the same time, high compressive strength can make it difficult to manufacture the insulation. PIR generally has a lower compressive strength than cellular glass, but this is sufficient to prevent most possible damage. This makes PIR insulation easier to manufacture. There are also higher density/strength PIR grades suitable for use in such locations as pipe supports where higher compressive strength is required.

Vapor barrier

Water is the primary foe of thermal insulation systems. When water vapor gets into the system, it condenses and often freezes inside the insulation system, which reduces its insulating capacity. Apart from this, it can result in a more frequent condensation of moisture on the outer surface and an increase in the flow of the heat.

If a sufficient amount of water vapor gets into the system, ice can emerge inside and on its surface, which can physically destroy it. Thus, in low temperature and cryogenic applications, an important component is a vapor barrier that prevents moisture from entering.

Usually, plant personnel can determine that the vapor barrier has failed in the system, as excessive moisture condensation and ice formation will occur.

As a larger amount of water enters the insulation system, and thermal performance deteriorates, ice can form on the outside of the metal shell. Since ice has a much higher thermal conductivity than the insulation itself, its presence in or on the system is an indication that more heat is being supplied to the system than is necessary. In addition, freezing water and its expansion can further damage insulation and vapor barrier systems if the problem is not solved.

It is rather difficult to repair an insulation system that has already been affected by ice. Therefore, the best thing to do is to correctly design and install a system with a reliable, durable and highly efficient vapor barrier from the outset.

Metal shell

No insulation system is complete without a metal shell, as it helps protect the system and vapor barrier from damage.

In addition, any metal shell must be protected against corrosion. For example, one option is a 76-micron thick three-layer polyethylene moisture-proof film that is laminated to the interior surface. This moisture barrier helps to reduce the predisposition of the shell to corrode.

Environmental conditions

Typically, thermal insulation systems need to be designed for the worst climatic conditions. This includes high humidity, high temperatures, and low wind speed. This is necessary even if the region has only one “difficult” month per year — for example, with a relative humidity of about 90% and an ambient temperature of more than 30°C.

Designing the system with this month in mind will ensure efficient operation throughout the year. But if the designers do not take into account one month of difficult environmental conditions, the system can fail.

The insulation system is an important and complex part of the entire project. It should be designed by experienced professionals familiar with the engineering aspects of such systems and installed by contractors experienced in the materials and systems used in such cryogenic systems.

When deciding on the insulation, designers should consider its physical characteristics and compare them to the specific needs of the system, as well as to the project’s budget and its limits.

Relevant articles