What works we perform.

In modern realities, the demand for the consumption of semi-finished products is growing rapidly. Products such as dumplings, fish and meat cutlets, pancakes, bakery products are in special demand.

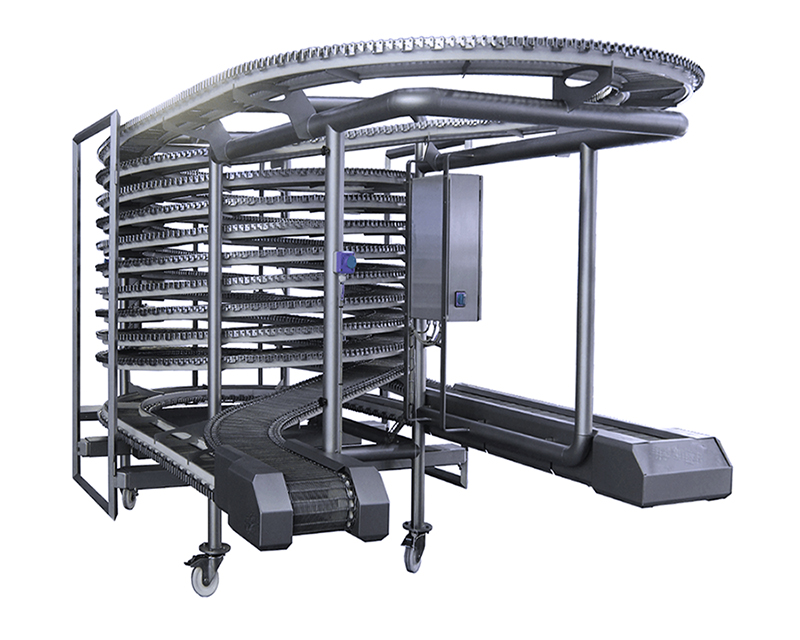

In addition to raw materials, technology and equipment for direct production, modern refrigeration equipment for rapid cooling and freezers for freezing semi-finished products are needed. These include: tunnel freezing, spiral low-temperature conveyor, shock freezing chamber, low-temperature storage chambers.

Production facilities and workshops, including work areas for staff, should also have relatively low temperatures, up to +10-14°C.

For additional cooling of air in rooms, low-speed ceiling two-stream air coolers are used. They provide not only maintenance of the set temperature, but also speed of movement of air to 0,2-0,3 m/sec which allows the working personnel to feel rather comfortable.

Comprehensive solutions for refrigeration systems for the production of semi-finished products.

We offer comprehensive calculation, design, supply and installation of systems for cooling, freezing and storage of semi-finished products, maintaining the microclimate in the premises using innovative and energy-efficient technologies.

Our experts will help you evaluate different types of refrigeration systems, select the most efficient and cost-effective technical solution that will meet your long-term maintenance requirements and budgets. We provide a warranty on the equipment from the manufacturer and the work performed.